Spin 360 Production for Tap and Shower Manufacturer

A major Spanish manufacturer of taps and shower systems commissioned us to produce Spin 360 visualizations for their entire product catalogue.

The objective was clear: progressively replace static photography with an interactive system capable of showcasing each model from every angle, while maintaining visual consistency across the full product range and enhancing the user experience on their corporate website.

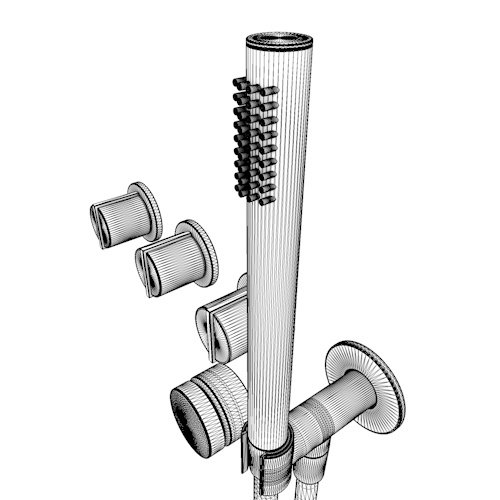

The challenge went far beyond generating rotational sequences. The real complexity lay in the technical quality and structural integrity of the provided 3D assets.

Technical Issues in 3D Models for Spin 360 Production

The supplied 3D models presented several common industrial limitations:

- Open or incomplete meshes

- Unsealed pipe inlets visible from certain angles

- Missing components that had never been modeled

- Incorrect normals affecting shading quality

- Non-calibrated materials lacking realism

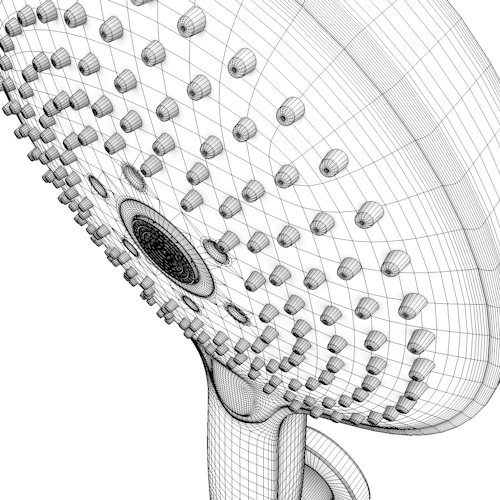

In a 360-degree rotation environment, every structural imperfection becomes visible. Elements that might go unnoticed in a static render are immediately exposed when the product is viewed from all angles.

3D Reconstruction and Optimization for 360 Rotation

Before production could begin, a complete technical refinement process was required.

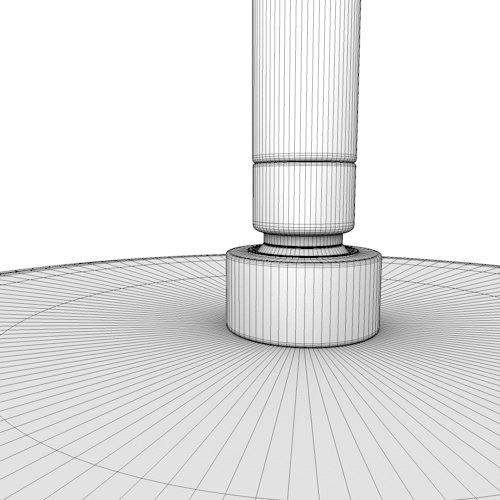

Missing components were rebuilt, non-existent parts were fully modeled, and all pipe inlets were sealed to prevent interior visibility during rotation.

Mesh topology was optimized to ensure stability in sequential rendering and consistent reflection behavior, particularly for high-gloss metallic finishes.

One of the most demanding aspects of the project was developing a lighting system adaptable to the entire catalogue.

The shower systems and taps included multiple finish variants: polished chrome, brushed steel, matte black, gold finishes, and combinations incorporating plastic components. A neutral yet effective lighting setup was designed to perform consistently across all materials without generating excessive reflections or loss of definition.

A replicable lighting framework was created to guarantee visual consistency across hundreds of product references.

Spin 360 Results and Web Integration

The project concluded with a fully optimized Spin 360 production, designed for seamless web integration and smooth performance across desktop, tablet, and mobile devices.

The manufacturer achieved:

- Visual consistency across the full catalogue

- Enhanced perception of product quality

- Clearer visualization of finishes and materials

- Clean integration within their digital ecosystem

This case demonstrates that professional Spin 360 production is not merely automated rotation. It is a technical process combining 3D reconstruction, lighting design, rendering strategy, and web optimization.

Did you like this project? Continue with another project.